sales@briocean.com

sales@briocean.com

English (EN)

English (EN)

sales@briocean.com

sales@briocean.com

English (EN)

English (EN)

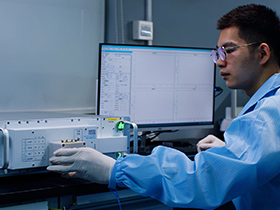

Stringent Quality Control System

At Briocean, we prioritize providing top-quality electronic components to our clients. We have established two advanced Quality Control Centres in Hong Kong and Shenzhen, spanning 1,000 square meters, and equipped with over 60 sets of inspection equipment and over 50 professional engineers. Our QCS management system covers all inspection processes, from warehousing to electrical testing, ensuring compliance with international standards. Our mission is to never let counterfeit products reach our clients.

Established two quality control centres in Hong Kong & Shenzhen

Established two quality control centres in Hong Kong & Shenzhen

Each QC centre spans across 1,000 square meters

Each QC centre spans across 1,000 square meters

Equipped with over 60 sets of inspection equipment

Equipped with over 60 sets of inspection equipment

A team of over

50 skilled and professional engineers

A team of over

50 skilled and professional engineers

Star Quality Inspection Framework

Briocean maintains a keen focus on fulfilling client’s requirements by delivering high-quality electronic components.

Specialisation

Always be there to understand customers’ needs and provide customised solutions for effective, on-time procurement.

Trackable

Every aspect of our sourcing process, from supplier assessment and quality control to warehousing and transportation, can be easily tracked for each component that we have acquired.

Assurance

Our rigorous testing equipments and skilled engineers provide assurance that the electronic components we procure meet the highest standards and meet our target objectives.

Reliability

Consistency is essential for building trust, which in turn is rooted in reliability. It is crucial for every member of our team to deliver their best consistently as every employee's performance impacts our quality standards.

Smart Quality Inspection Process

Briocean implements a rigorous 4-tier quality inspection process to ensure that all electronic components meet the highest standards of quality. The first tier involves a visual inspection of the components to check for any physical defects or abnormalities. The second tier includes testing the components to ensure that they meet the required specifications and performance standards. The third tier consist of conducting a comprehensive reliability test to ensure that the components can perform under different conditions and environments. Additionally, Briocean offers an optional fourth tier, where Briocean collaborate with a third-party inspection entity to conduct further testing. This multi-tiered approach allows Briocean to provide high-quality electronic components that are reliable and perform optimally in a range of applications.

Testing Services

We understand our customers have unique requirements. As part of our effort to offer better services, we provide continuous training to our employees and upgrade our equipment regularly.

We understand our customers have unique requirements. As part of our effort to offer better services, we provide continuous training to our employees and upgrade our equipment regularly.

10 Testing Services we offer:

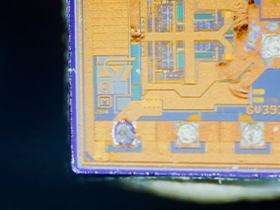

X-Ray Non-Destructive Flaw Inspection

Static Parameter Test

Impedance Analysis Test

ESD Anti-Static Test

Solderability Testing

High Temperature Aging

XRF Elemental Measurement and Analysis

Decapsulation

SAM Failure Analysis

MCU Programming Test

Certifications

Our attention on quality is backed by third-party certifications and memberships.